How Effective Bridge Maintenance Can Prevent Disaster

Effective Bridge Maintenance is essential in order to ensure your bridge is safe, sound and secure. As large components of modern infrastructure, bridges are built to last – but not forever. Many of the bridges found around the country were constructed decades ago, every day edging closer to the end of their intended lifespan. Even modern bridges are not immune to these issues. Constant use and exposure to a range of environmental factors mean that they too require regular maintenance.

The secret to easy bridge maintenance is in being proactive rather than reactive. This requires us to look for ways to safely manage structural issues before serious damage occurs.

Effective Bridge Maintenance is essential in order to ensure your bridge is safe, sound and secure. As large components of modern infrastructure, bridges are built to last – but not forever. Many of the bridges found around the country were constructed decades ago, every day edging closer to the end of their intended lifespan. Even modern bridges are not immune to these issues. Constant use and exposure to a range of environmental factors mean that they too require regular maintenance. The secret to easy bridge maintenance is in being proactive rather than reactive. This requires us to look for ways to safely manage structural issues before serious damage occurs.

How Effective Bridge Maintenance Can Prevent Disaster

This is a process by which a thermal camera creates an image of the bridge using radiation. The bridge itself will emit different levels of heat in different areas. This system will allow the infrared machine to construct a clear image of the entire structure. An innovative piece of technology, infrared thermography can easily locate voids, fluids and delamination’s (fracturing of the material into layers), allowing remediation experts to conduct the required repairs before any catastrophic failures.

Identifying How Much Reinforcement A Bridge Has

The use of devices like magnetometers allow us to detect iron inside of the bridge. Magnetometers can be thought of as more-or-less large scale metal detectors. They work in a similar fashion, just much more powerful. These machines are capable of detecting metallic material through more than 10 feet of concrete, allowing us to locate reinforcement beams and dowel pins. A pachometer can also be used when locating steel reinforcements. This more precise tool is able to give us a comprehensive understanding of the metallic reinforcement’s dimensions, with readings accurate to 0.1 inches.

Preservation Techniques

Concreate Repair - Professionally repairing any cracks, chips or spalls on the bridge will prevent further corrosion from occurring within the bridge.

Waterproofing - Sealing the surface will reduce the overall maintenance required and extend the lifespan of the bridge by providing the structure with a chemically resistant barrier.

Expansion Joints - The installation of expansion joints allow a bridge to breathe. These movement joints take the pressure off the bridge, giving the structure the ability to expand and contract without resulting in any damage.

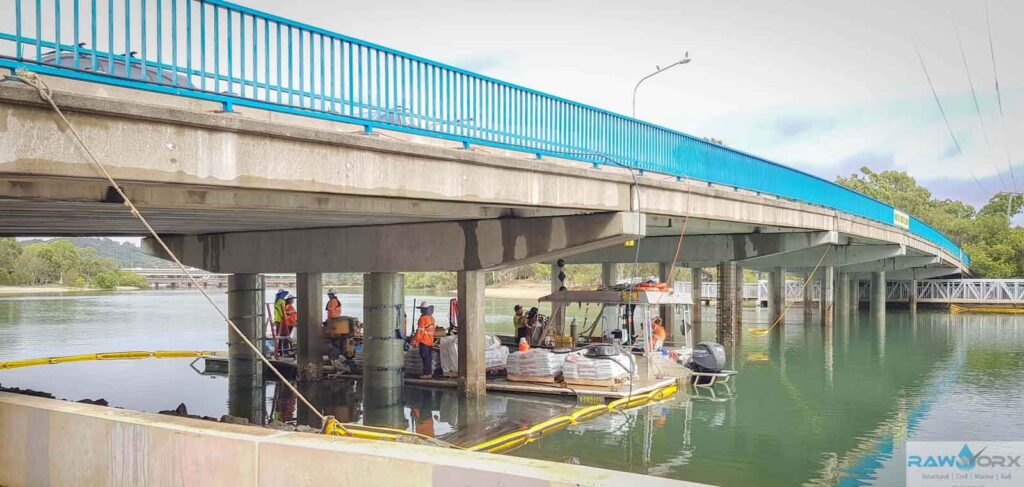

Jackets Around Concrete Piles - A very effective way to prevent corrosion underneath a bridge, these extra layers of coating can help a great deal in high moisture environments.

Making Sure Drainways Are Cleared - Collected water and debris can build up on the surface of the bridge and result in a lot of wear. Making sure a bridge is clean of rubbish and that all drains are free-flowing is an essential part of effective bridge maintenance.

Bridge Maintenance Experts In Australia

If you’re in need of professional bridge maintenance, contact Raw Worx today. We operate all around Australia, specialising in marine services along the country’s east coast in areas like Melbourne, Sydney and Queensland. As professional civil contractors, Raw Worx provides high quality, affordable bridge remediation services, concrete repairs and more. Over 10 years of experience in our field has made Raw Worx a name you can trust!